This is the transcript for my most recent video about Lab Meat

Lab meat is not going to save the planet or the animals. So then why has $3 Billion dollars been invested into Lab-meat startups? Well to understand the full picture, we’ll have to first look at the science of why making lab-meat at scale is so complicated, let’s take a look at why it’s so expensive, why it could be worse for the environment and finally we’ll look at how investors sometimes invest in optimistic stories not based in reality.

At first, I was optimistic about lab meat - it made so much sense. Growing just a steak instead of a whole cow should be way more efficient. But then I started looking into it... and it made less and less sense.

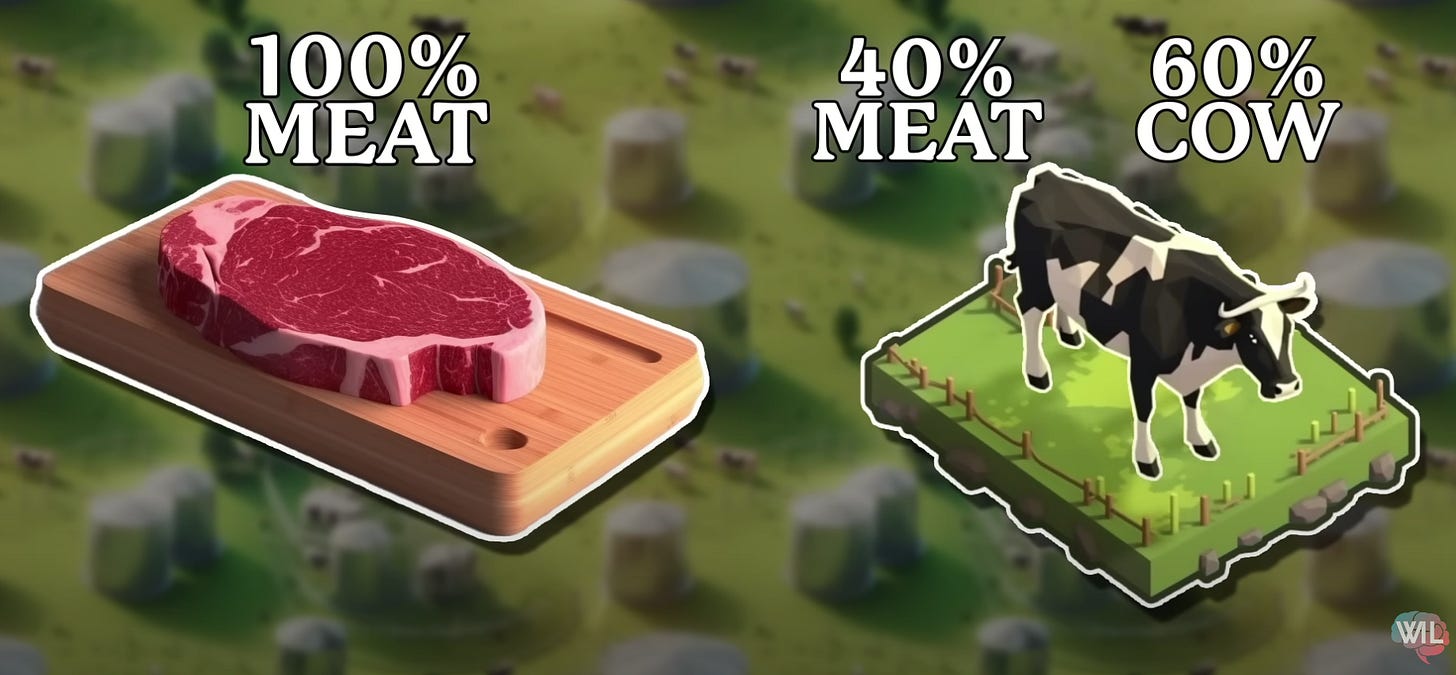

* Source for animation - Cow is 65% meat

To take cells from a cow or chicken and grow them quickly, they need to be put in a very expensive custom-made bioreactor filled with a specially formulated liquid made with purified water, growth factors, purified amino acids, glucose and salts. A cow …just needs rain water and grass.

The facility and the bioreactor need to be totally sterile because a tiny amount of bacteria or virus could ruin the whole batch wasting tons of money. A cow has an immune system so it can lay in the dirty grass outside.

A huge challenge to growing cells quickly is developing ways to efficiently deliver oxygen and nutrients to each cell while removing waste products like ammonia, lactate and CO2. A cow handles all this easily with lungs, blood vessels and its liver.

…and there’s a lot more to this picture but it’s very expensive to do what a cow, chicken or pig does.

The lab-meat company Eat Just was actually selling lab-grown chicken nuggets straight to consumers in Singapore, but those cost upwards of $50 each to make. For that same price, about 1500 nuggets could be made from conventional chicken meat.

The most common justification for lab meat is that we need it to prevent conventional meat from destroying the planet. At the cultivated meat symposium, when an audience member asked what the need for cultivated meat is, the host said so that we have a planet to inhabit. Ezra Klein, founder of the hugely popular news media company Vox, wrote an article arguing that we need government funding into plant-based protein and lab meat to save the planet from climate change. But … Dr. Derrick Risner points out in his PhD dissertation that despite all the hype and investment that has already been poured into lab-meat, a detailed assessment of whether lab meat is actually better for the environment has not been properly done.

One report commissioned by The Good Food Institute, GFI, a non profit which heavily promotes and supports the lab-meat space, projected that it would cost $450 million dollars to make a facility producing a mere 22 million pounds of lab meat a year.

That sounds like a lot but if this steak represents the 100 billion pounds of normal meat the US makes a year, this represents 22 million pounds - a mere .022% of US meat production. And 450 million is the extra optimistic price tag, another analysis put the cost of such a facility closer to $5 billion. Meaning that even if we assume lab-meat has zero emissions, a trillion dollars worth of facilities would reduce global emissions by 1/20th of one percent.

・Emissions from Livestock in North America makes up 0.9% of Global Emissions per GLEAM v3.0

・22 million pounds * 200 facilities = 4.4 Billion pounds, 4.4% of of U.S.’s annual meat production

In 2021, Joe Fassler published a bombshell article in The Counter that laid out the specific technical details illustrating why lab meat is very likely pipe dream. One of the many experts Fassler consulted with was David Humbird, a chemical engineer who wrote the most detailed analysis of scaling lab meat yet.

Even in the most generous best-case hypothetical scenario Humbird considered, where various economies of scale are included and all kinds of technological and scientific breakthroughs are assumed to have happened, he projected that lab-meat in the future would still be very very unlikely cost under $11 dollars per pound to produce. With Markup, it would easily be over $22 a pound at the supermarket - over 4 times the price of normal ground beef.

So, why is it so damn expensive?

Again, the problem is not growing a bunch of lab-meat, it’s growing it for cheap so people will actually buy it. It’s not as simple as scaling up your equipment -it has to do with biological limits. Humans exist, but you can’t have a 10 foot tall human. You can have a really big animal, but you can’t have a big animal with a really fast metabolic rate.

You can grow cells outside of an animal in a large bioreactor, but not efficiently. If you want to grow just the beef we eat cheaply and efficiently… you need the rest of that cow.

The 2 huge problems limiting efficient cell growth in a bioreactor are.

-Getting oxygen and nutrients to the cells.

-Transporting CO2 and waste products away from the cells.

First, Mammals’ complex vascular system is responsible for delivering oxygen and nutrients to all their cells. It’s arranged in an intricate fractal pattern such all 100 trillion cells are within a mere 500 microns of a small capillary.

With lab meat, the cells are just dumped in a liquid that has the nutrients they need, and the mixture is stirred around to help expose all the cells to the nutrients. Oxygen is delivered to the cells by blowing bubbles into the tank. This nutrient liquid is only able to carry an amount of oxygen that is 45 times less than what real blood can carry.(S)

By the way, this nutrient liquid is currently so expensive and resource intensive to make that PhD in Food Science and Technology Dr. Derrick Risner’s analysis suggests lab-meat may have a much higher environmental impact than normal meat.

The pharmaceutical industry has been using tons and tons of bioreactors to make all sorts of products for decades now - globally, about 23% of all drugs are made in bioreactors. If we’re going to start using bioreactors for meat, we are going to need a ton of them. Pretend this steak represents global meat demand. This is half of one percent. That is how much lab meat we would get if we had 11 to 22 times the the entire pharmaceutical industry’s current stainless steel bioreactor capacity just for growing lab meat.(S)

As part of normal cell metabolism, CO2 and waste products like ammonia and lactate are produced by the cells. It’s almost like the cells are sitting in their own urine - when too much of these things build up in the tank, the cells don’t do too well and it reduces the rate that the cells grow. At some point the cell growth will slow to a halt and your cells will die from bathing in all that urine, so before that happens you need to harvest your cells and start a new batch.

David Humbird explains in his 2021 paper that biological limits like this are more often the issue than physical limits like tank size. Meaning, you could have a 250,000 liter tank but it would be completely worthless if your cells stopped growing at say only 20,000 liters because of too much CO2 or ammonia build up.

In the case of a cow, its bloodstream would simply transfer the CO2 away from the cells to the lungs to be breathed out and ammonia and lactate would be transported to the liver to get rid of it.

With bioreactors… there is a process called perfusion which can clear out some of the CO2 and ammonia which improves cell growth, but that equipment is way too expensive to use for making millions of pounds of lab meat. Humbird calculates that even though you are growing cells more efficiently, it would cost even more - driving up the cost an extra $6 per pound.

This is just one of many problems that need to be solved to make lab meat cheap enough for the average person to buy.

Lab Meat isn’t Meat

First of all, what usually comes out of these bioreactors is called cell-slurry, a watery mash of cells that doesn’t feel or taste like real meat as is…

So most future lab-meat products will be blended with other non-meat ingredients and formed into homogenized things like burger patties, nuggets, sausages, meatballs and hot-dogs.(S)

Real meat is composed of various types of cells - it has its familiar texture thanks to both muscle fibers and fat cells as well as blood vessels, tendons, connective tissues and so on. But, bioreactors typically can only cultivate one single type of cell at a time meaning an entirely different process will be needed to assemble various cells and additives together into a texture that resembles something like a steak, or porkchop.

Several of the compounds that contribute to the flavor and nutritional profile of meat arrive there thanks to processes going on elsewhere in the animal’s body - these things don’t just appear in the cells. So to match real meat, various nutrients and compounds will need to be added one by one at some point in the process.

So, a lot of work will need to be done to get consumers to actually like it much as real meat.

Broken Promises

The lab-meat industry has a history of making promises they can’t keep. In 2021, Mother Jones published an illustration of the many many predictions made by research institutions and lab-meat companies about when lab-meat would be available that ended up being wrong.

Don’t be naive about the power of Story Telling

This is Josh Hoffman, he was the CEO of the synthetic biology company Zymergen. His skill of painting a vision for the future earned Zymergen $1 billion dollars of venture capital.

Microbes will change basically everything we touch and feel

He had an optimistic vision of reducing our reliance on petrochemicals by producing everyday products like anything from optic film to mosquito repellant in bioreactors. These bioreactors would be filled with microbes specially engineered to produce specific compounds we regularly rely on petrochemicals for. But the challenge was the same as lab-meat’s : how would they ever do this at scale for a reasonable price?

Zymergen went public in April 2021. But just 4 months later they announced they would bring in zero dollars in product revenue for 2021 and 2022 and their stock tanked 69%, wiping out 2.5 billion dollars in market value.

CEO Josh Hoffman left Zymergen in August of 2021 and by July of 2022, 94% of the company’s stock value had vanished since going public. A former employee said that Josh Hoffman mislead people with exaggerated financial figures and made overly optimistic projections about the company’s capabilities.(S)

One of the big players in the lab meat space Eat Just has raised over $800 million dollars in venture capital. Eat Just came under scrutiny in 2016 when they sent many of their workers into grocery stores to buy out tons of their vegan mayonnaise product to inflate sales figures. A former scientist at the company said this type of behavior was common. Eat Just has been sued for not paying various bills for a total of about 3million dollars.(S)

In 2022, Eat Just made the impressive announcement they will be building 10 never-before-seen 250,000 liter bioreactors.

An ex- Biopharma consultant and board member of Cellular Agriculture Australia, Dr. Paul Wood commented on this saying “Now that is just infeasible” and he said that the claims were more about virtue signalling to investors than good science or manufacturing practice.

[See my video for snippets from my interview with Paul Wood]

Eat Just claims their 250,000 liter bioreactors will be able to produce 30 million pounds of meat a year by 2030.(S) These big numbers may wow investors and earn them more investment, but even everything goes perfectly to plan, their magic facility would replace a mere .03% of the United States conventional meat production.

Even Yaakov Nahmias - CEO of the lab-meat company Believer Meats says that a quarter of a million liter bioreactor is just a fantasy.

Nahmias explains that while a bigger bioreactor would help scale the production, it makes the cell growing process less efficient as you very quickly get issues with increased pressure at a mere 20,000 liters which affects factors like oxygen delivery to the cells.

In a webinar hosted by the Good Food Institute, Dr. Maryanne Ellis acknowledges that scaling up lab meat will require a massive amount of steel. She says the goal is to have bioreactors even in places like slums and refugee camps, so we should focus on getting more cells per bioreactor, instead of trying to make huge bioreactors. However Derrick Risner says that logic doesn’t necessarily follow. Let’s say you have 2 facilities producing the same amount of lab meat. One has a single 100,000 liter bioreactor, another has 20 1000 liter bioreactors that produce 5 times more cells. This facility with a total volume of only 20,000 liters actually uses more steel than the single 100,000 liter bioreactor.

Another huge difficulty with massive lab-meat plants is that they need to be exceedingly clean. A bioreactor doesn’t have an immune system to protect the fragile animal cells so if the tiniest bit of bacteria, virus or other contaminant on a worker’s gloves or clothing gets into these massive bioreactors, the entire batch of cell slurry would be ruined. This is a well known million-dollar problem with bioreactors in the pharmaceutical industry

Some people have used the misleading analogy that a lab-meat facility will basically be like a beer brewery. This is far from the truth considering beer can be made in your backyard while you’re smoking a cigarette and wearing the same sweaty clothes you had been wearing at the gym.

An extra clean lab-meat facility handling the same volume as a beer brewery could be well over 6 times the price due to all the measures necessary to keep it clean like for example Level 6 and Level 8 clean rooms that constantly purify the air.

Back in 2017 when Eat Just was selling vegan mayo products, all of their products were pulled off of the retailer Target’s shelves after allegations of food-safety problems like listeria and salmonella contamination at the manufacturing facility.(S) Let’s hope they are able to keep their lab-meat facilities cleaner or they could be wasting millions of dollars.

Speaking of contaminants, as revealed by their own data submitted to the FDA, a different company’s lab made chicken had 5 miligrams of lead per 100g - more than the safe daily limit for children … which is 3 micrograms.(S)

When talking to Joe Fassler, Dr. David Humbird summed up the feasibility of scaling lab-grown meat as a big wall of NO. He even said it was a fractal “no,” that the big No is composed of many smaller No’s.

Despite Humbird being as generous with his analysis as possible, he still found that lab meat could not become cheap enough to be practical.

Derrick Risner has written two papers that point out the extreme cost and resource intensity of preparing that nutrient liquid, the growth medium for the cells. He agrees with Humbird’s saying lab-meat is a big wall of No.

However, in late 2022, Yaakov Nahmias, founder of Believer Meats announced that his team’s new work growing cells in the lab had conclusively shattered Humbird’s so-called big wall of No. Which is pretty big - after reading about this, I thought I might have to rewrite this entire video. Believer Meats approach is to increase the number of cells in the bioreactor by getting rid of those toxic waste products like ammonia and lactate we talked about earlier. More cells in the bioreactors means more meat at a lower cost.

In their experiment, they used a perfusion device - it’s kind of like an artificial liver that pumps fluid in and out of the bioreactor and clears out the toxins. They claim that using this technique allowed them to get to a number of cells per liter that is way higher than what Humbird said would be possible.

That sounds exciting at first, but these results were done in a mere 2 liter bioreactor. If we’re talking about what can be done at very small-scale in the lab, this isn’t actually new at all. Another team already achieved similar cell-growth results way back in 2013 and it was with less resource intensive equipment. To mass produce lab-meat at commercial-scale, we need bioreactors that handle 1,000s of liters.

Derrick Risner pointed out that the pharmaceutical industry will often attempt to scale in multiples of 4. So, if you achieved 2 liters in the lab, the next step is to run an experiment at 8 liters. Then if that works you could try 24 liters, then 96 liters and so on. You don’t just jump from 2 to 1000.

In fact, I got in touch with another expert who is familiar with the specific perfusion devices Believer Meats used in their lab. He said that using the same methods, we shouldn’t expect those perfusion devices to handle a bioreactor bigger than even 50 liters.

When it comes to cost, Dr. Nahmias himself acknowledges that using this type of perfusion technology is so expensive that it’s not appropriate for commercial scale production of lab-meat. This left me confused about how Believer Meats work done at very small scale the lab “shatters” Humbird’s paper on the … scale-up economics of growing meat in bioreactors.

Last year, Dr. Jeffrey Lee Funk published an article titled Fake it till you make it’ is an old trick Silicon Valley startups use to get money. He explains the cycle of how startups are often overly optimistic to the point of misleading investors into investing, but then people see that investment as evidence that the company is likely to succeed which drives more investment.

Bruce Friedrich is the CEO and Founder of the earlier mentioned Good Food Institute. He was featured in Ezra Klein’s article, saying public investment in lab grown meat is urgently needed. Joe Fassler wrote in his article that when Friedrich was skeptically questioned by Ricardo San Martin who has a PhD in biotechnology , Friedrich snapped back that the fact that people have invested is proof that scaling lab-meat is practical.

There is a surprising number of over-funded, house-of-cards startups today. As laid out by Dr. Jeffrey Funk, Uber has raised 25 billion dollars but their cumulative losses are 32 billion. We work raised 21 billion with cumulative losses of 20.7 billion. Even Gingko Bioworks which acquired the earlier mentioned company Zymergen has raised 800 million dollars but has cumulative losses of 3.3 billion. Throwing money at companies doesn’t make them profitable, so why should we assume throwing money at lab-meat will make it cheap to produce?

One reason why that perfusion technology is so expensive is that it uses tons of that expensive growth medium. The cost of growth medium has been a concern for the bio processing industry for decades, yet various lab meat companies act as if it’s a given that this will be solved soon.(S)

So as things are now, lab meat is a kind of Catch-22

-If you want to make a lot of lab meat efficiently, you need a big vessel

-But it’s really difficult and expensive to keep big vessels clean

-And the bigger the vessel, the less efficient the cells grow

-You can use perfusion to make your cells grow more efficiently but perfusion is expensive

-and perfusion doesn’t scale … it uses too much expensive growth medium

-and making tons of growth medium is too resource intensive and bad for the environment

Some companies are aiming to make hybrid products instead, for example they’ll just make animal fats in bioreactors and use that to make plant based products taste better.

Perfect Day is a company making synthetic whey protein using fungus in a fermentation tank. They mix that with water, sugar, sunflower oil and other ingredients to make a milk-like product. Even though this type of fermentation is typically way less resource intensive than growing meat in bioreactor, their animal-free milk product currently costs about 3 times as much as Organic Grass Fed Milk (S) and about ten times as much as regular milk.

The optimistic of us may still assume that just like how Moore’s law allowed us to go from Macintoshes to Smart Phones we’ll go from $50 chicken nuggets to $5 lab steaks. But… Moore’s Law doesn’t apply to biological systems… but even if it did, Moore’s Law is plateauing lately - it can’t go on forever. Lab-meat technology may improve, but at some point the progress will hit a plateau. Thinking that that plateau won’t come before lab meat’s cost is practical is a huge gamble.

About $3 billion has been invested into lab-meat so far Yet, theavailable evidence does not show lab-meat will be profitable or good for the environment. Nonetheless, lab-meat companies will probably continue to attract plenty of investment with faithful optimism.